Protocells

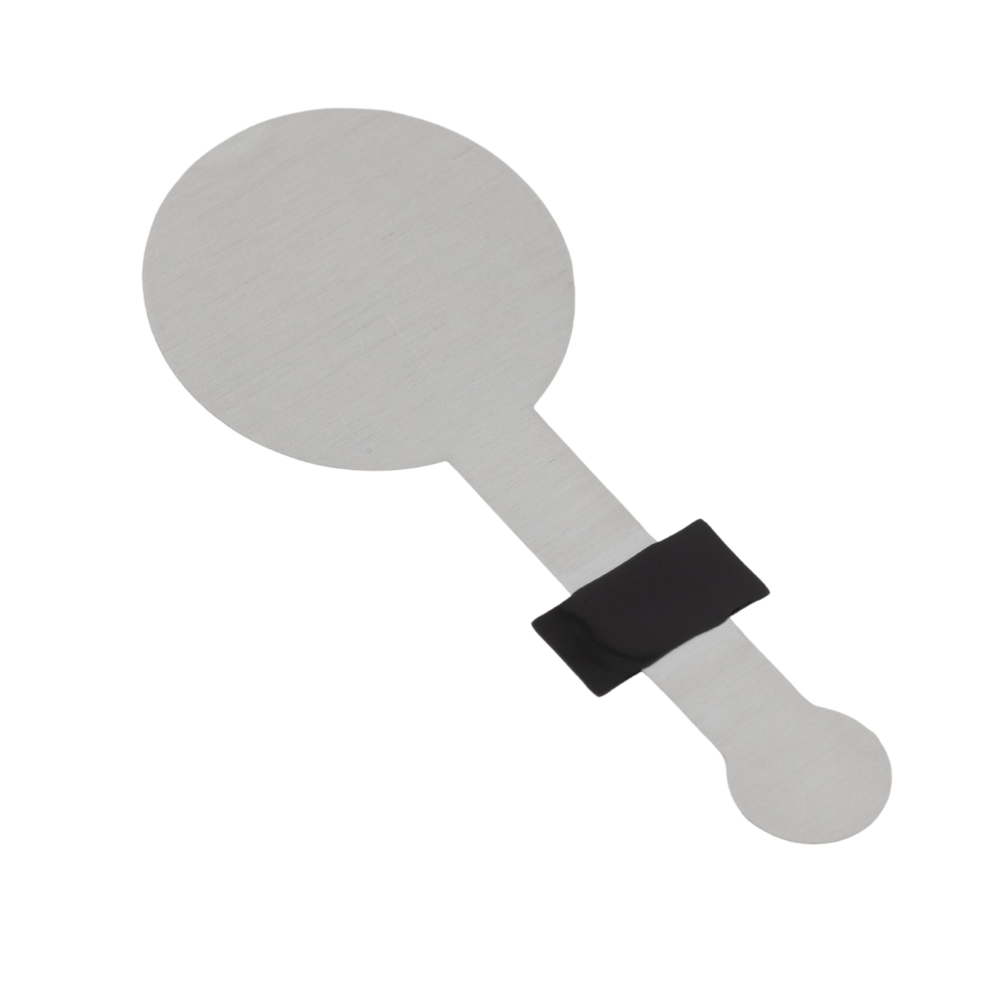

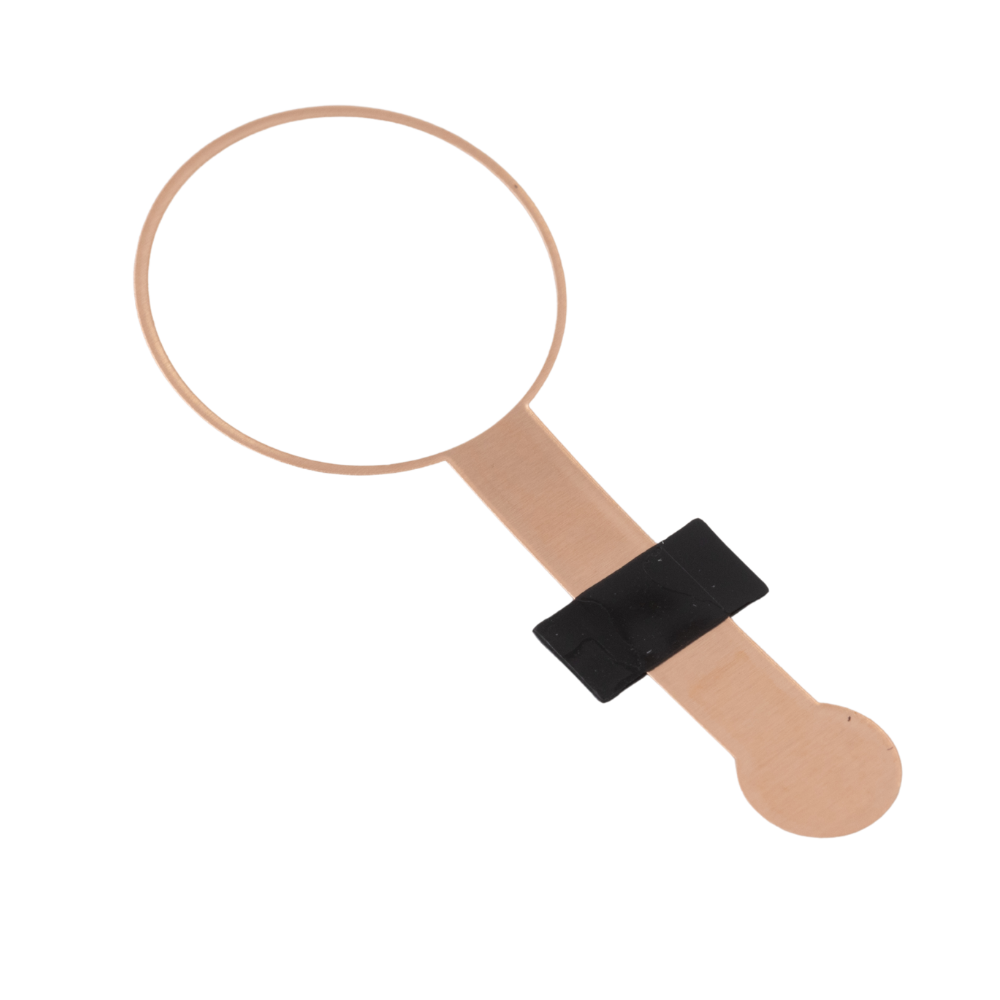

Coin Cells In A Pouch

Test coin cell type electrodes in our new pouch format.

Coin Cells Were Made for Watches, Protocells Are Made for Research

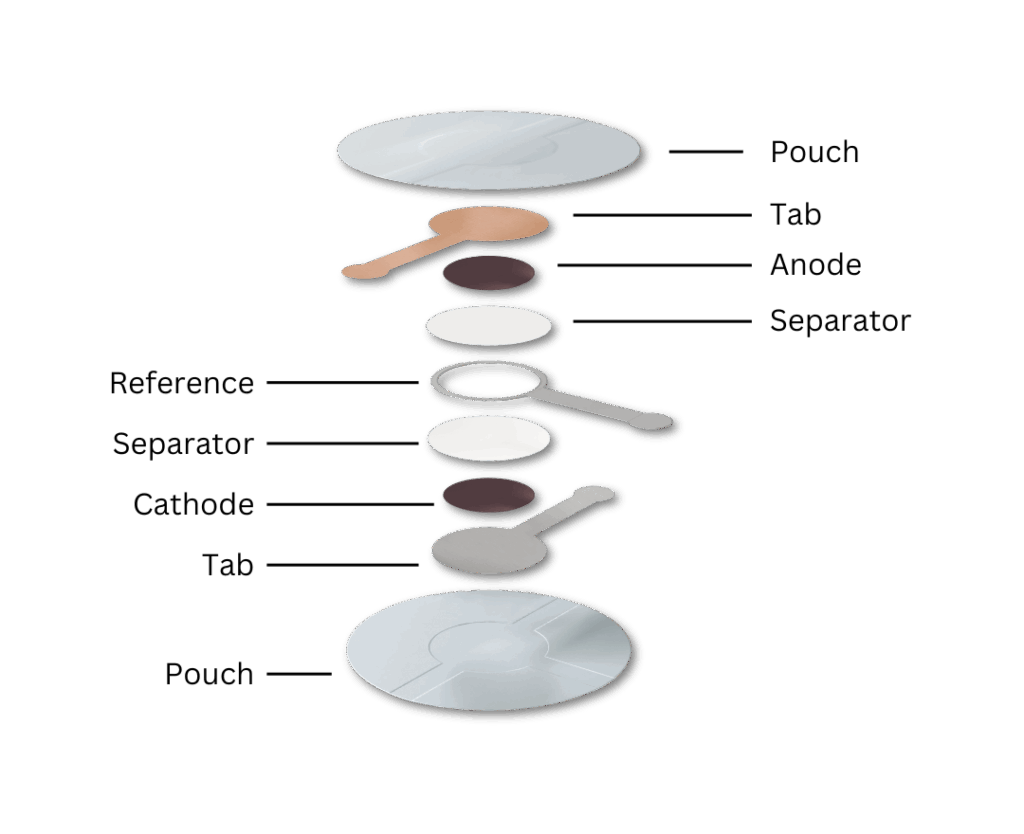

Protocells enable unparalleled control and accuracy in electrochemical testing. Developed to bridge the gap between traditional coin cells and pouch cells, Protocells allow direct control of pressure and electrolyte volume, whilst also enabling, reference electrode integration, and easy disassembly for post-mortem analysis.

Cellerate’s Protocell format has been adopted by leading research institutions, and material developers, offering a more representative and scalable testing environment for next-generation battery chemistries.

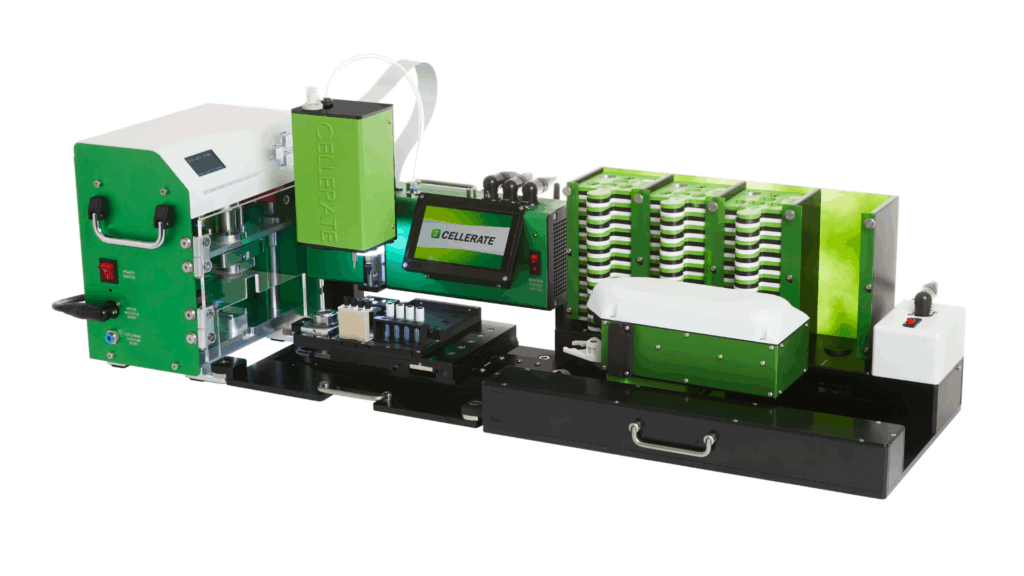

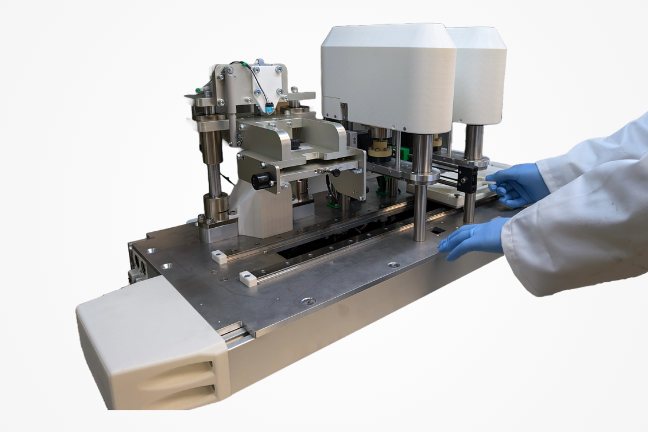

Automatically Assemble Protocells With Our Cell Assembly & Sealing System

Load Protocell Components

Automatic Protocell Assembly

Protocells Ready For Testing

Why Protocells?

Protocells are engineered to overcome the inherent limitations of coin cells, offering a superior data-driven approach for evaluating electrode and electrolyte performance. Their pouch-style architecture leads to data that is more representative of the commercial scale, allowing researchers to extract quality insights even with small sample sizes.

Key Research Challenges:

- How do you test materials under realistic pressure conditions?

- How do you precisely control electrolyte volume?

- How do you evaluate each electrode independently with a reference?

- How do you streamline post-mortem analysis?

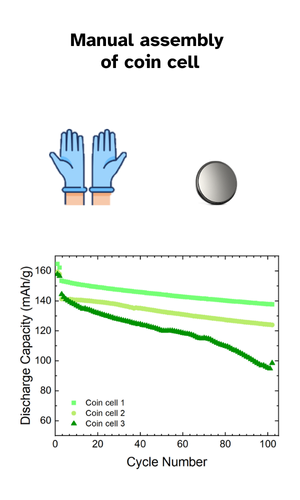

Comparison of Coin Cell vs Protocell discharge capacity

Graphite anode (NEI NANOMYTE BE-200E), NMC-622 cathode (NEI NANOMYTE BE 54E), Celgard separator, 1 M LiPF6 in EC:EMC (3:7) + 1wt.% VC [Solvionic]. Both coin cells and Protocells were assembled using the Cellerate CASS to remove the ‘human factor’. Protocells tested under 0.4 MPa stack pressure.

Protocell Technical Specifications

| Component | Specification |

|---|---|

| Pouch Material | 110 µm laminated aluminium |

| Electrode Compatibility | Standard coin cell-sized electrodes (10 mm – 16 mm) |

| Reference Electrode | Range of materials available. 17 mm ring, 16 mm inner diameter |

| Separator Size | Up to 19 mm |

| Tabs | 17 mm contact area, 0.1 mm thick with hot-melt tape – no tab welding required |

| Sealing Method | Heat-sealed under vacuum |

| Integration | Compatible with Cellerate CASS for automated assembly and sealing |

Protocell Test Holders & Pressure Jigs

To maximise the capabilities of Protocells, Cellerate offers a specially designed test holder and pressure jig for cell cycling and other electrochemical tests.

The Protocell Test Holder ensures stable, long-term electrical contact to anode, cathode, and reference tabs for high-accuracy measurements. It connects seamlessly to most standard cyclers and enables 2 or 3 electrode configurations with minimal setup.

The Protocell Test Holder slots into the Pressure Jig to allow researchers the precise control of the electrode stack pressure, making this ideal for commercially relevant testing, scale-up, and also solid-state battery research.

Test Holder & Pressure Jig Options

| Feature | Specification |

|---|---|

| Electrical connection | 4-point Kelvin with reference tab |

| Stack pressure control | 0.05–10 MPa (manual or motorised) |

| Dilation Measurement Precision | 0.05 μm |

| Contact Stability | Designed for reliable long-term testing |

| Environmental Compatibility | Suitable for use inside environmental chambers |

A New Benchmark For Coin Cell Research

Protocells combine the simplicity of coin cells with the functionality of pouch cells, giving researchers a test platform that scales with their ambition.

- Rapid switching between coin cells and Protocells

- Automated assembly with CASS

- Higher quality, more representative data

- Easier post-mortem characterisation

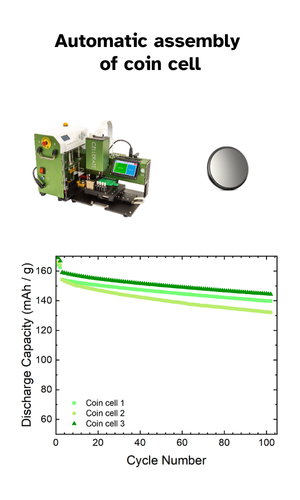

Which Cell Format Is Right For You?

Discover Our Systems

Cell Assembly & Sealing System

Automated assembly of coin cells and single-layer pouch cells for material testing and quality control. Achieve high precision and high throughput cell assembly without spending hours in the laboratory.

Multi-Layer Pouch Cell Assembly

This new approach to automatic pouch cell assembly enables rapid reconfigurability, accelerating discovery across R&D and quality control while saving lab space.

Electrode Preparation System

The Electrode Preparation System from Cellerate offers a fully automated solution for cutting, weighing, and measuring electrodes for coin cells and small pouch cells with unparalleled precision.