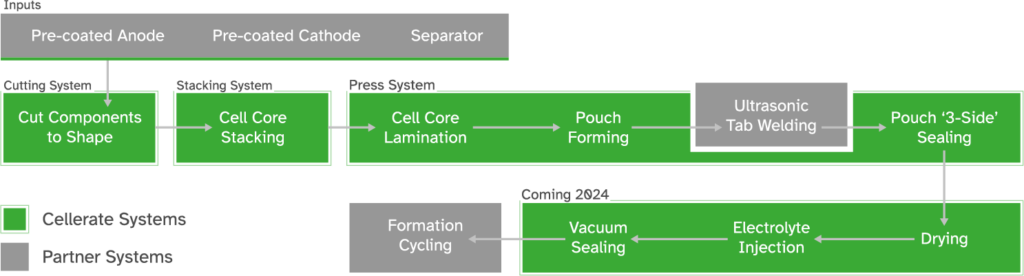

Multi-Layer Pouch Cell Assembly

Unleash the Full Potential of Your Technology

The Cutting System

The Cutting System is available with laser-cutting and blade-cutting capabilities, and it includes an intuitive user interface for seamless operation. Despite its compact size, it is capable of throughputs up to 1000 electrodes per hour, and includes advanced features such as automatic unloading of cut components and automated electrode inspection.

The Stacking System

The Stacking System automatically stacks pouch cells in custom geometries for a diverse range of applications. It is easy to reprogram for making different cell designs, can make 2 x 40-layer cells per hour, and can achieve a maximum stack height of 200 cell layers.

The Multi-Functional Press

The Multi-Functional Press replaces three large presses with one, space-saving unit. This is our all-in-one solution for consolidating the pouch forming, cell lamination and 3-side sealing processes.

Cellerate’s flexible solution for rapid cell prototyping enables optimised cell design for organisations that want to produce 100 to 1000 multi-layer pouch cells per week. The three elements of our system work together to allow you to explore novel cell formats and prototype application-ready cells while saving on both lab space and staff time.

Designed by

Battery Scientists,

For Battery Scientists

Unleash the potential of your chemistry. Benefits of Cellerate’s innovative approach to cell prototyping include:

- Quick changing between cell geometries.

- Creation of application-specific demonstration cells.

- Exploration of performance at a larger scale.

- Easily adaptable to different electrode materials and separator types.

- Lithium metal compatible.

Let’s talk

Want to make better batteries faster? Contact us!