Electrode Preparation System (E-PREP)

Automate Your Electrode Preparation for Superior Battery Research

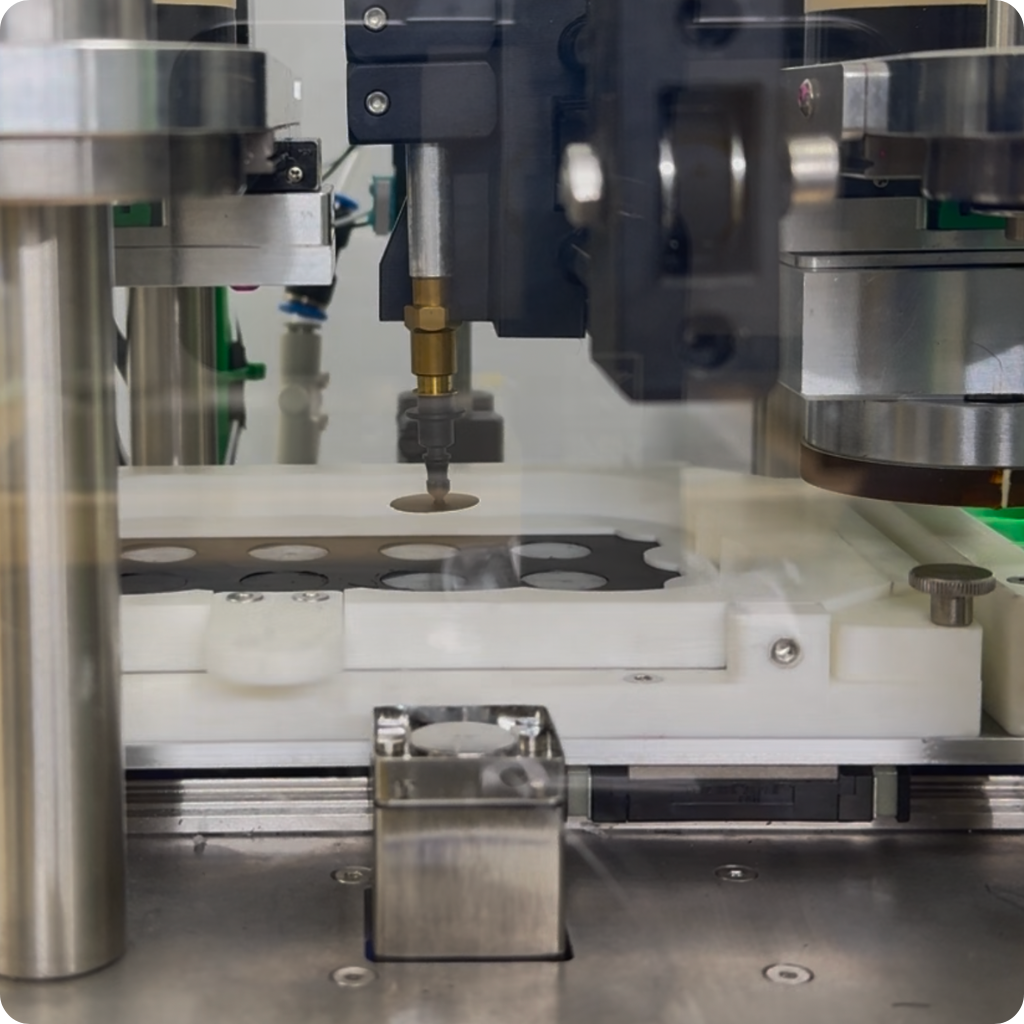

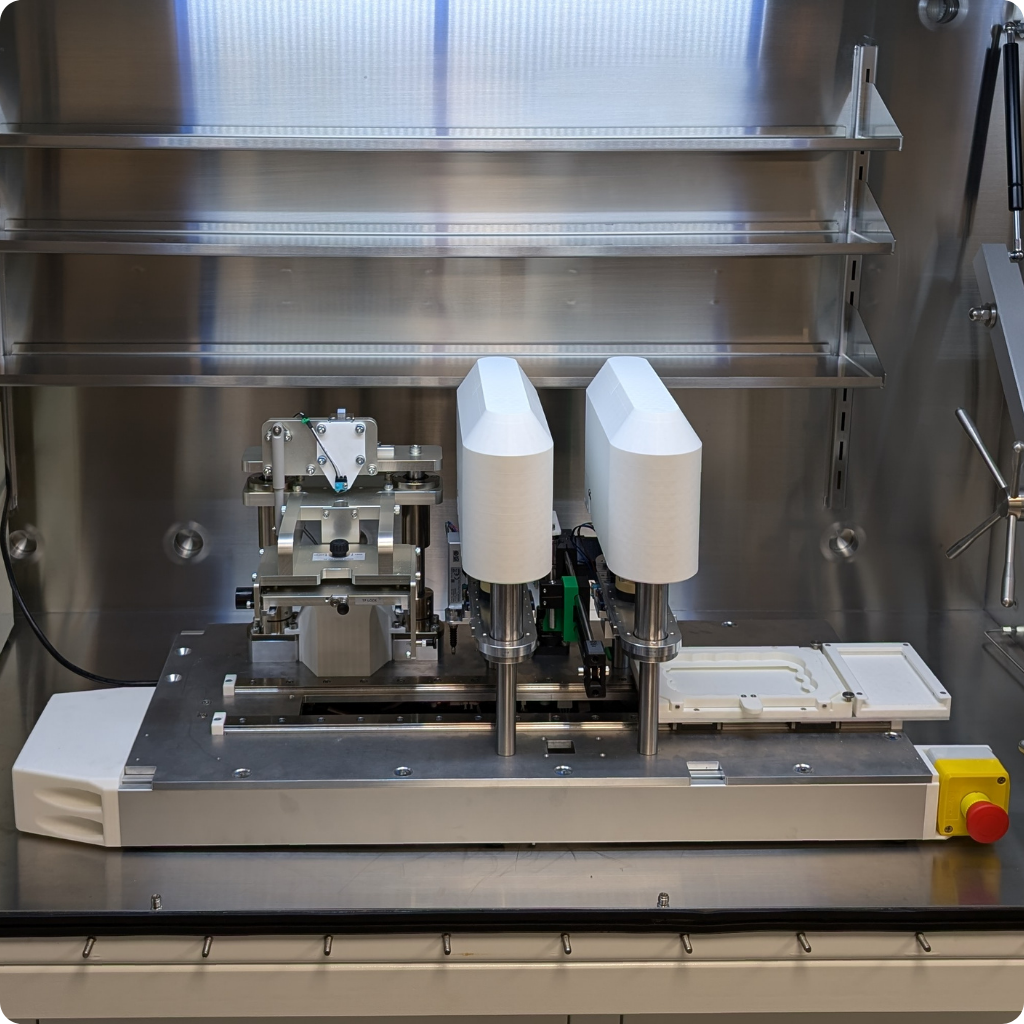

The Electrode Preparation (E–PREP) System from Cellerate offers a fully automated solution for cutting, weighing, and measuring electrodes for coin cells and small pouch cells with unparalleled precision. Developed in collaboration with the Centre for Process Innovation (CPI), the E–PREP System streamlines your workflow, from material preparation to cell assembly, reducing manual handling and ensuring consistent, high-quality results every time.

System Features

Designed for Safety

Minimal manual handling reduces the risk of damaging delicate electrode coatings.

High Throughput Efficiency

Processes hundreds of samples per week, reducing manual workload and increasing lab productivity.

Seamless Integration

Prepared electrode discs are ready for direct insertion into the Cellerate Cell Assembly & Sealing System (CASS).

Why Choose E-PREP?

The E-PREP System is ideal for:

- Battery R&D Labs: Automate the electrode preparation process to increase efficiency.

- Quality Control Facilities: Ensure consistent sample preparation and data accuracy.

- Material Testing Environments: Quantitative verification of electrode properties.

Maximise Efficiency: Free up skilled staff for high-value research tasks.

Improve Data Quality: Consistent, repeatable sample preparation improves research reliability.

Reduce Manual Errors: Automation minimises human error in the electrode preparation process.

Simplify Your Workflow: Seamless integration with the CASS for a streamlined lab experience.

System Specifications

The System

Size and Weight: 1000 x 350 x 300 mm (WxHxD), 70 kg

Power Requirements: 80 – 260 V accepted, 240 W peak power

Throughput: Up to 60 electrodes per hour

Thickness Measurement System

Probe: Mitutoyo Linear Gauge LG100

Precision: ± 1 μm

Sheet Dimensions (min): 50 x 50 mm

Sheet Dimensions (max): 150 x 100 mm

Cutting System

Tool: Knife die (laser option available)

Electrode Dimensions: Up to 19 mm disc, or custom shapes on request

Customisation: Compatible with a wide range of die shapes and sizes to suit your application

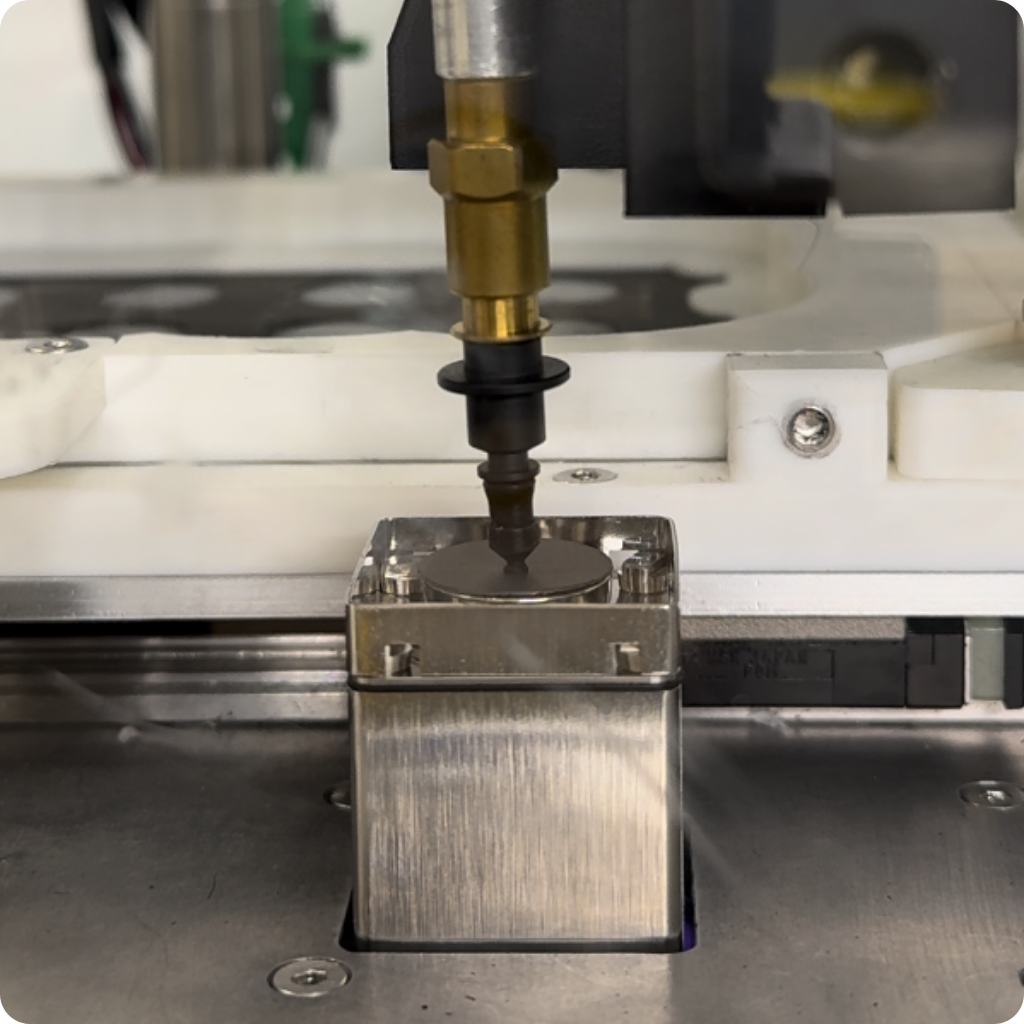

Resistance Measurement System

Probe: Hioki RM2610

Measurement Parameters: Composite resistivity (Ωcm) and interface resistance (contact resistance) between the composite layer and current collector (Ωcm²)

Number of Probes: 46

Weighing System

Microbalance: Mettler Toledo SPC115-111

Precision: 0.1 mg (0.01 mg option available)

Can’t find what you’re looking for? We provide customised systems to meet your needs.

Let’s talk

Want to make better batteries faster? Contact us!