How Vianode Increased Cell Yield and Lab Efficiency with Cellerate Automation

Discover how a leading synthetic graphite manufacturer scaled their R&D output and improved data reliability, without increasing hiring more staff.

“Cellerate enabled us to test more materials, with fewer people, and more confidence in our data.” — Vianode R&D Team

The Challenge: Manual Coin Cell Assembly Slowed Progress

Vianode is a Norwegian company specialising in the production of sustainable synthetic anode graphite for lithium-ion batteries. Their laboratory operations require the production of hundreds of high-quality coin cells each week to validate the material performance. But manual cell assembly had become a bottleneck.

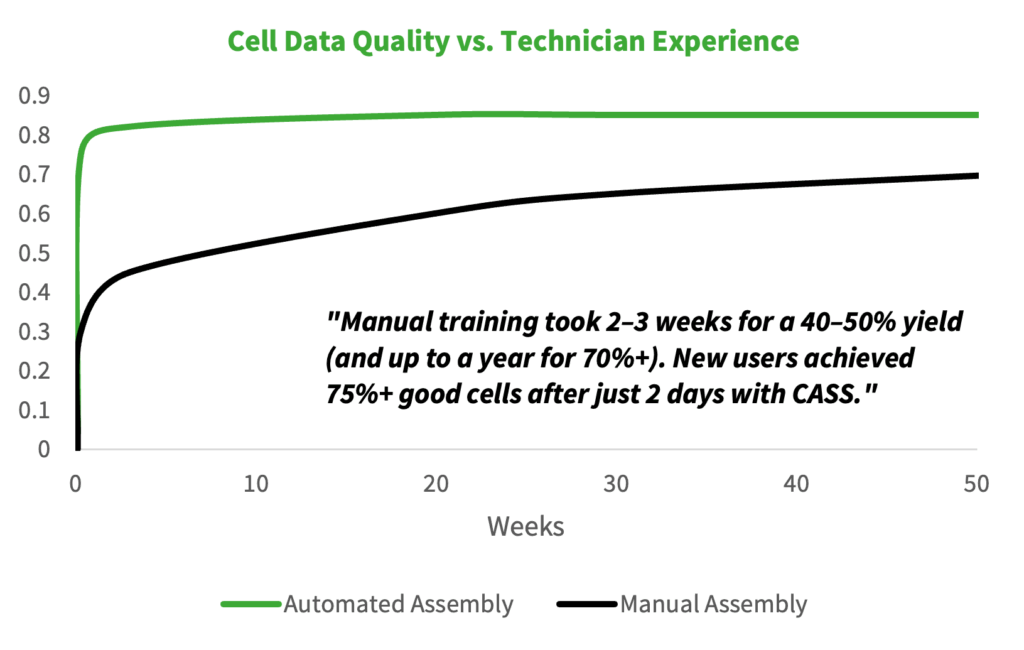

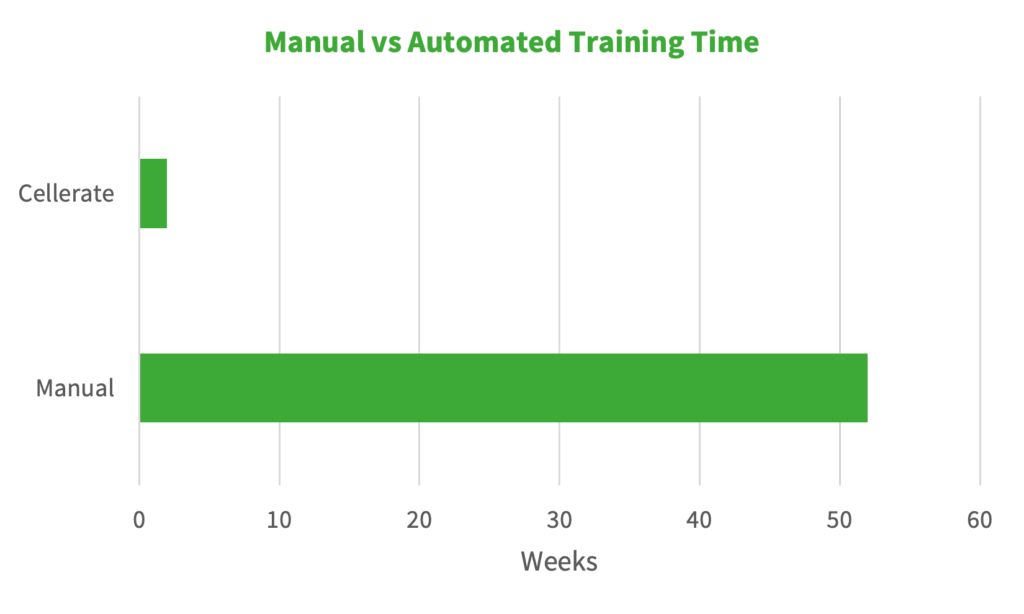

Despite an experienced team, only 79% of cells consistently met Vianode’s high standard (≤1% variation in key metrics). Training new technicians could take up to 12 months, and building a single batch consumed an entire working day. As pressure mounted to validate more materials, it was clear the manual process was no longer sustainable.

The Solution: Cellerate’s Cell Assembly & Sealing System (CASS)

To solve this, Vianode integrated the Cellerate Cell Assembly & Sealing System (CASS). The system required no infrastructure changes and was easy to use, even for new team members.

Within two weeks, new users were assembling high-quality coin cells independently. CASS replaced time-consuming manual steps with precision and repeatability, allowing the team to scale output and focus on higher-value tasks.

The Results: Higher Yield, Faster Output, Better Data

Training time reduced from 12 months to 2 weeks

New users achieved 75%+ success rates in just two days, improving team flexibility and reducing onboarding costs.

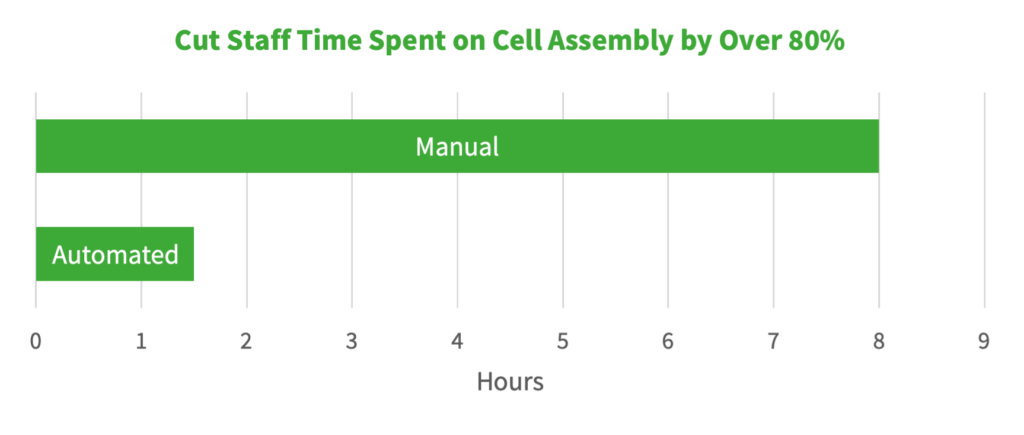

25–30 technician hours saved per week

Manual assembly that once took a full day can now be prepared in 1.5 hours, followed by an unattended run, freeing up staff to work on innovation, not repetition.

67% reduction in cell-to-cell variability

OCV variance was cut by two-thirds compared to manual builds, supporting more confident, data-driven decision making.

Scientific Reliability at Scale

Using CASS, Vianode built over 450 cells across eight different technicians, maintaining <0.3% standard deviation in performance. The system’s machine vision and QC tools ensure each cell is built consistently, no matter who is operating it.

Yield increased to 85%+

CASS raised the number of ‘good cells’ (meeting Vianode’s ≤1% variation threshold) from 79% to over 85%, with less variability, even across multiple technicians.

Conclusion: A Smarter, Scalable Future for Cell Assembly

Vianode’s experience shows that automating coin cell assembly isn’t just about speed; it’s about building a robust foundation for scientific progress. By implementing CASS, they unlocked new levels of efficiency, reliability, and scalability and set the stage for further automation across the battery development lifecycle.

Interested in Improving Your Lab’s Throughput and Data Quality?

Read our full Case Study or contact us to discuss how CASS can improve your workflow.

Let’s talk

Want to make better batteries faster? Contact us!