Protocells: Reliability, Precision & Flexibility for Battery Researchers

Battery researchers have relied on coin cells for decades, but the format often limits how well laboratory results translate to real-world pouch cells. Variations in stack pressure, sealing, and electrode alignment can all affect performance data, making it harder to compare results or scale discoveries.

Cellerate developed Protocells to bridge this gap. Combining the convenience of coin cells with the mechanical realism of pouch formats, Protocells provide a controlled and repeatable environment for testing new electrode materials and electrolytes.

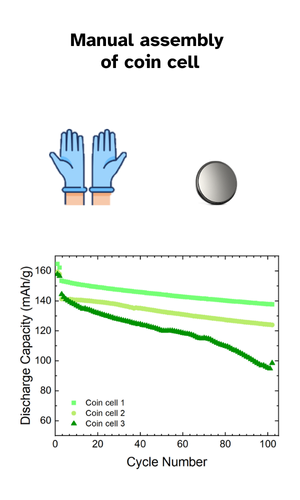

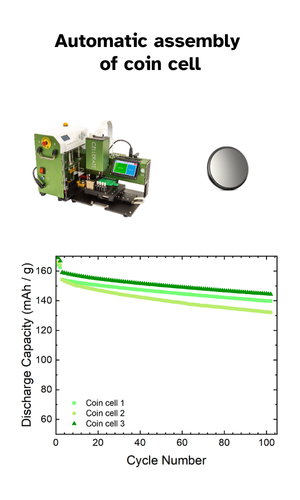

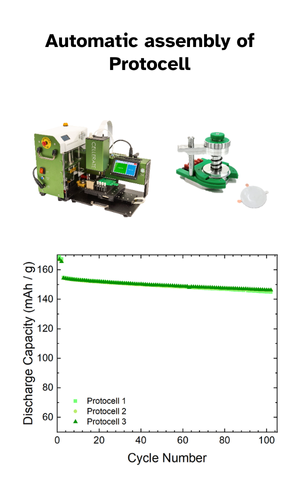

The Impact of Stack Pressure Control On Cell To Cell Consistency

Protocells deliver greater cell-to-cell consistency than traditional coin cells when using the same materials. Their laminated aluminium pouch design, along with the bespoke Protocell testing jig, allows stack pressure control, eliminating inconsistencies caused by manual crimping. This results in clearer, more reliable electrochemical data that can be confidently compared across experiments.

Both coin cells and Protocells can be assembled using Cellerate’s automated Cell Assembly & Sealing System (CASS), removing human variability and ensuring identical construction each time. Protocells tested under controlled pressures of 0.4–0.6 MPa consistently show improved performance reproducibility.

Comparison of Coin Cell vs Protocell discharge capacity

All cells were assembled with ‘off-the-shelf’ components. Graphite anode (NEI NANOMYTE BE-200E), NMC-622 cathode (NEI NANOMYTE BE 54E), Celgard separator, 1 M LiPF6 in EC:EMC (3:7) + 1wt.% VC [Solvionic]. Both coin cells and Protocells were also assembled using Cellerate’s CAS System to remove the ‘human factor’. Protocells tested under 0.4MPa stack pressure.

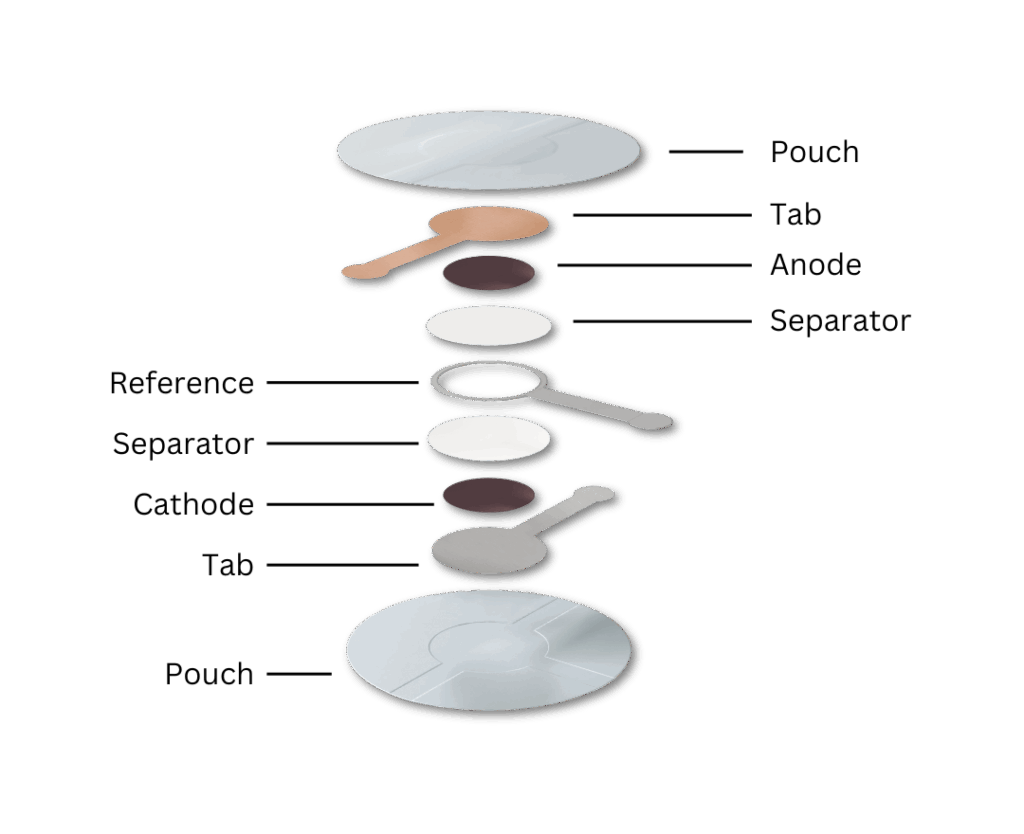

Flexible Reference Electrode Options

Protocells support a wide range of reference electrode configurations, allowing researchers to study individual electrode behaviour in detail.

Options include:

- Carbon rings

- Lithium rings

- Gold wire electrodes

- LTO & LFT (coming soon)

Or make your own with our uncoated Al/Cu/Ni/SS reference electrodes.

Don’t need a reference electrode? – Protocells can also be assembled with only two electrodes, allowing the flexibility and precision of the Protocell technology with your current test procedures.

Real-World Testing Conditions

When combined with Cellerate’s Protocell testing jig, researchers can apply precisely controlled, uniform pressure throughout cycling. This mimics real pouch cell behaviour and produces data that translates directly to larger-scale formats.

The result is a test platform that supports faster material screening, improved failure analysis, and more confident progression from lab discovery to commercial validation.

Setting a New Standard for Battery R&D

Protocells serve as a stepping stone between coin cell research and large-format pouch cell development, helping researchers transition their material discoveries towards commercial applications.

- Easily switch between making Protocells and coin cells with the same equipment, reducing lab space requirements.

- Protocells are transforming how the next generation of energy storage materials are tested, providing unprecedented control, accuracy, and reliability.

With their ability to enhance research consistency, improve failure analysis, and integrate into automated workflows, Protocells are a critical tool for accelerating battery innovation.

Technical Specifications

| Component | Specification |

|---|---|

| Pouch Material | 110 µm laminated aluminium |

| Electrode Compatibility | Standard coin cell-sized electrodes (10 mm – 16 mm) |

| Reference Electrode | Range of materials available. 17 mm ring, 16 mm inner diameter |

| Separator Size | Up to 19 mm |

| Tabs | 17 mm contact area, 0.1 mm thick with hot-melt tape – no tab welding required |

| Sealing Method | Heat-sealed under vacuum |

| Integration | Compatible with Cellerate CASS for automated assembly and sealing |

Learn more about Protocells and how they can enhance your research

Click the button below to read our full Protocell Whitepaper or contact us to find out more.

Let’s talk

Want to make better batteries faster? Contact us!