Researchers in America’s Battery Belt Use Cellerate to Improve Data Confidence

The Rise of America’s Battery Belt

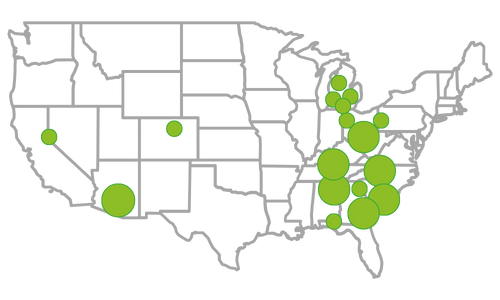

The Battery Belt in the United States is rapidly becoming the heart of global battery innovation. Stretching from Michigan to Georgia, it’s home to a growing cluster of research institutions and manufacturing hubs that are accelerating the clean-energy transition.

But even the most advanced labs face a familiar challenge of achieving reproducible, consistent data when assembling small test cells by hand. Manual coin-cell builds often introduce tiny inconsistencies that can distort results and slow progress, which is why automation is key.

A Familiar Challenge

A leading American research institute studying lithium and sodium chemistries told us they struggled with variability in manually built coin cells. Minor differences in alignment and occasional damage to thin electrode foils made it hard to tell whether changes in performance were caused by material properties or build quality.

These challenges mirror those faced by many laboratories across America’s Battery Belt, where precision, repeatability and data confidence are essential to stay competitive.

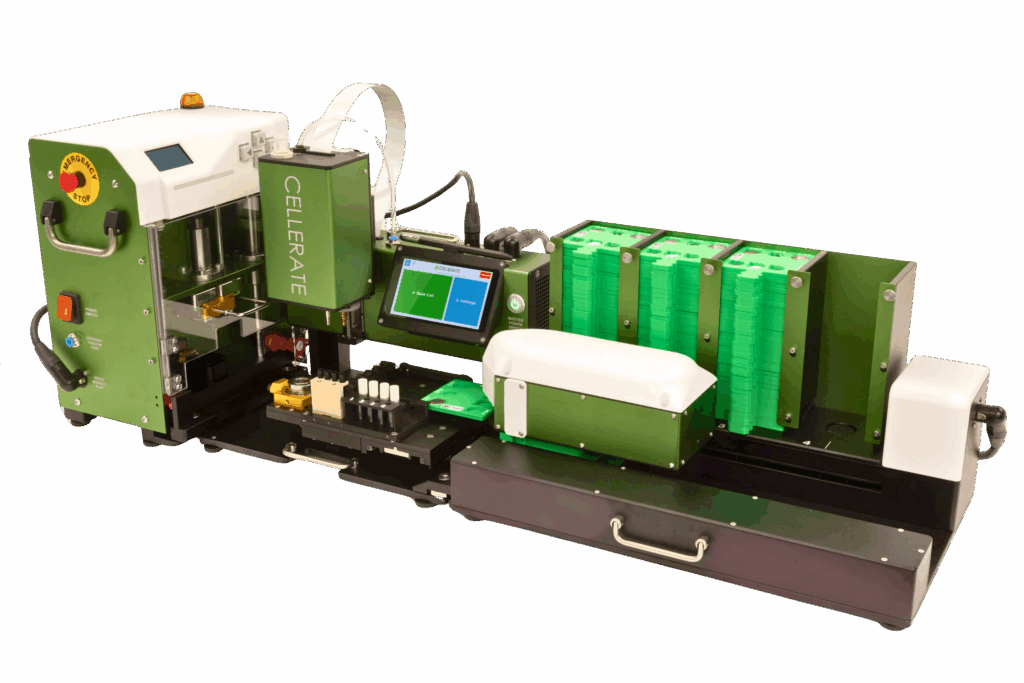

To overcome these issues, the institute implemented Cellerate’s Cell Assembly & Sealing System (CASS), an automated benchtop platform developed in the UK and used by research and industrial R&D teams worldwide.

The system’s vacuum nozzles precisely handle delicate foils, while integrated machine-vision cameras ensure perfect electrode alignment. Each cell build generates image logs that provide full traceability and confidence in data accuracy.

Whereas traditional automation focuses on throughput, CASS is designed for flexibility, ideal for R&D environments where priorities, chemistries and materials are constantly changing.

“Automated alignment and image logs give us confidence that differences are material-related, not from build quality.”

Researcher from an American research institute

The Impact

By automating precision assembly, the research team reduced uncertainty in their results and gained stronger confidence in the conclusions drawn from electrochemical data.

Researchers now attribute performance variations to the material itself rather than build inconsistencies, leading to more reliable testing and faster experimental iteration.

“The implementation and setup were easy, and learning to operate the system confidently only requires ~1 hour of training.”

Researcher from an American research institute

Cellerate’s expansion into the U.S. Battery Belt highlights a growing partnership between British engineering and American research excellence. By combining advanced automation with the ingenuity of U.S. laboratories, Cellerate is helping to strengthen the foundation of next-generation battery research, ensuring that discoveries made in the Battery Belt are backed by repeatable, high-quality data.

To discover more industry research, visit our resources page

Let’s talk

Want to make better batteries faster? Contact us!