The Cell Assembly & Sealing System

The Future of Cell Assembly

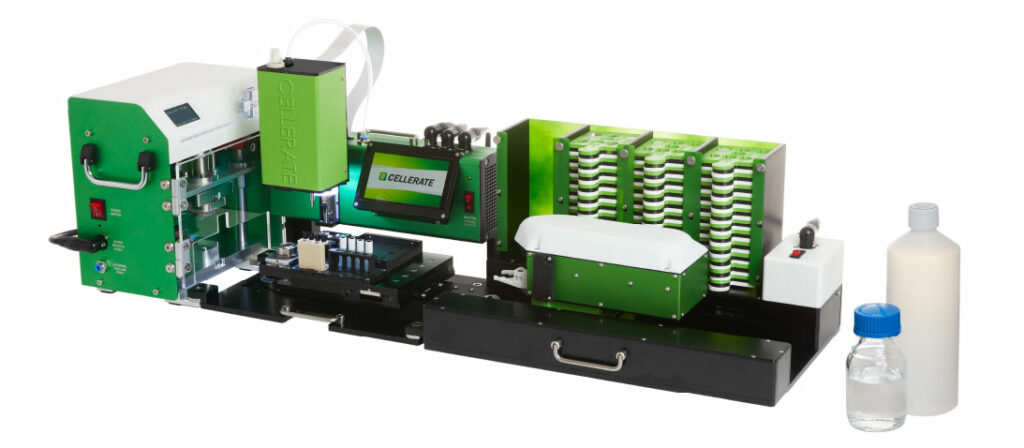

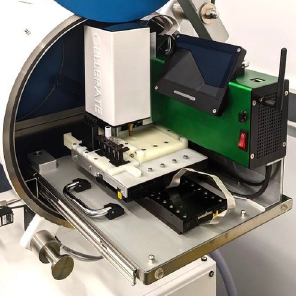

The Cell Assembly & Sealing System is a fully automated, benchtop machine that builds single-layer cells with speed and precision. Designed to fit through the antechamber of a two-glove glovebox, this system makes it easier than ever for research and quality assurance labs to test cells of the highest standard.

Build both coin & pouch cells

Save time & improve build quality

System Features & Specifications

Straight to Scale-Up

Easily swap between coin cells and pouch cells in under 5 minutes.

Use proto-cells instead of coin cells to achieve pressure control, 3-electrode testing, and easy disassembly for post-mortem analysis.

Scale up your research by making single-layer pouch cells with electrodes up to 40 × 60 mm.

Supercharge Your Battery Research

Save Time with Automatic Loading

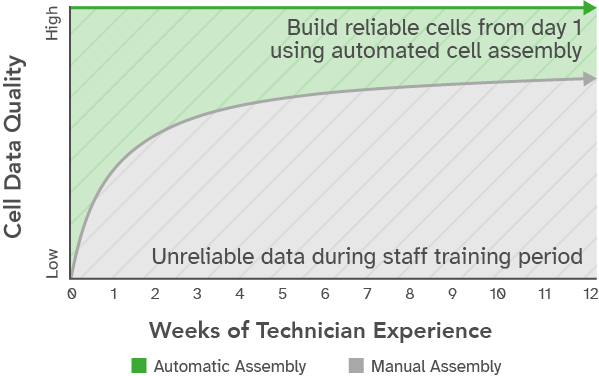

Lower the skill barrier to cell assembly

Automated Quality Control

Flexible Electrochemical Exploration

Build coin cells and pouch cells with the CAS System in either full-cell or half-cell configuration. Add a reference electrode and control electrode stack pressure using our next generation proto-cell format.

System Features

Fully Automated Cell Assembly

Accurately assembles up to 20 cells per hour with less than 200 μm axial misalignment between electrodes.

Switch Between Coin and Pouch Cells

Quickly switch between coin and pouch cell building to enable rapid technology scale up.

Generate Build Procedures

Using our intuitive build procedure generator you can configure the order in which components are assembled.

Easy Workflow Integration

All modules are designed to go through the antechamber of a standard, two-port glovebox.

Simple and Intuitive to Use

With the Cellerate System anyone can build a cell. Just load components into the tray and press build.

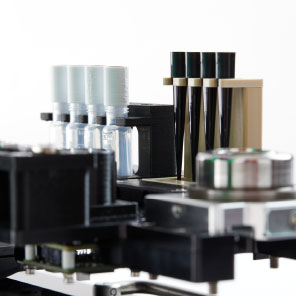

Controlled Electrolyte Dispensing

Accurately dispense 5-200 μL of electrolyte at once. Can be dispensed at different stages of build procedure.

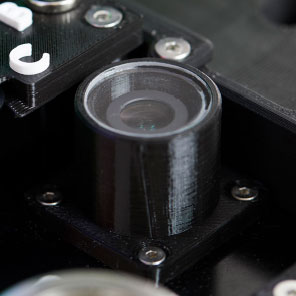

Smart Electrode Alignment

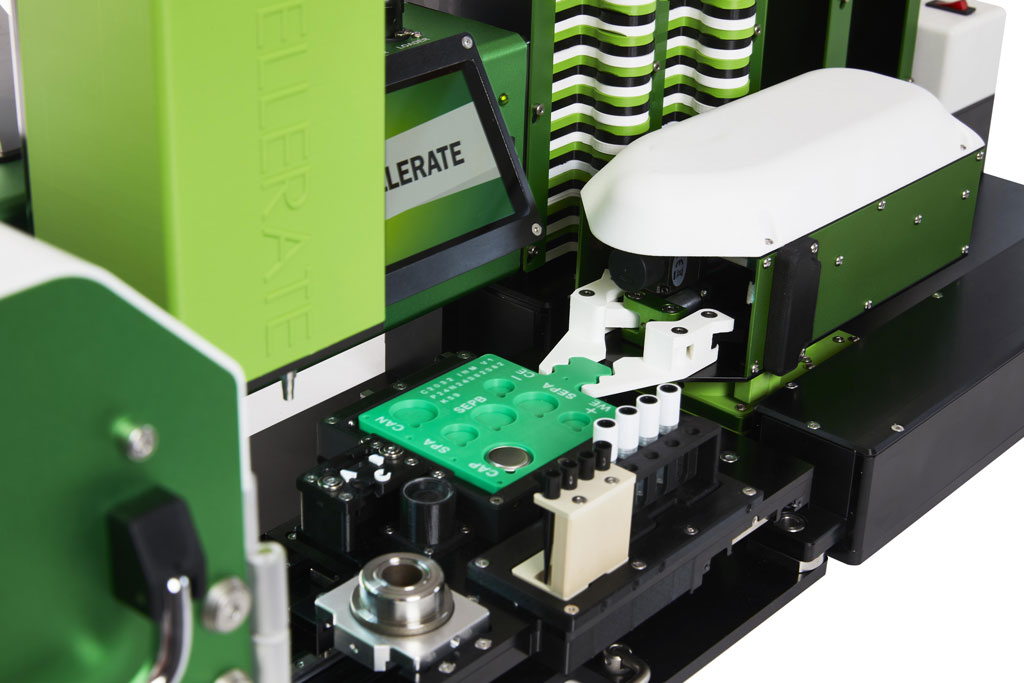

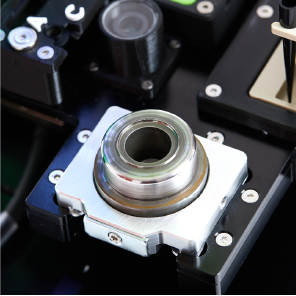

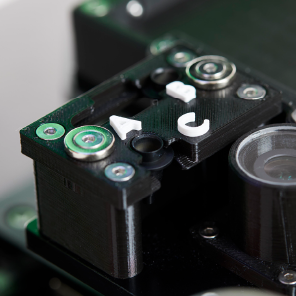

Patented machine vision technology ensures even curved electrodes are accurately aligned.

Explore Electrolyte Parameter Space

Dispense electrolytes and additives from multiple vials. Combine by ratio to explore parameter space.

Avoid Cross-Contamination

Automated head exchange allows the operator to avoid contamination, especially important for Li metal.

System Specifications

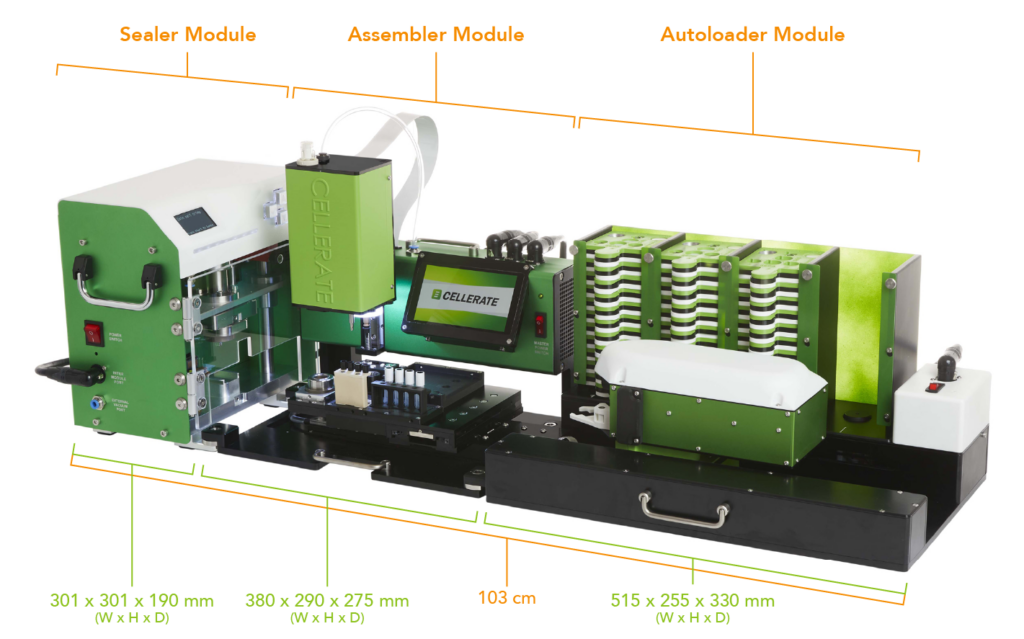

Full System

Features

– Fully automated cell assembly

– Fits through glovebox antechamber

– Assembles up to 20 cells per hour

– Patented machine vision technology

– Mean electrode alignment within 100 μm

– User friendly interface

– 5-200 μL robotic micropipette

– Automated head exchange avoids cross contamination

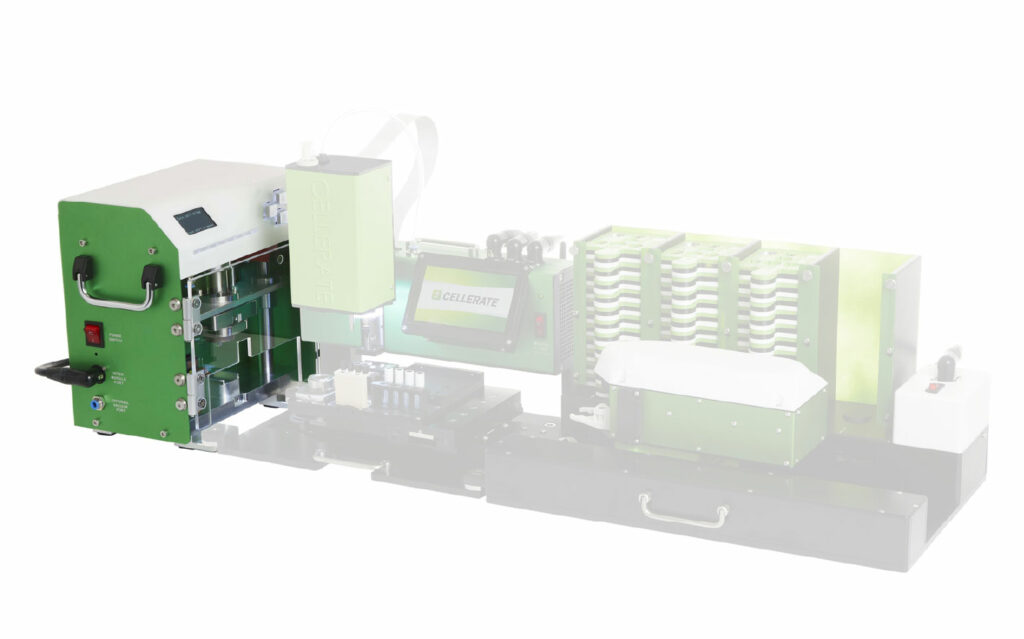

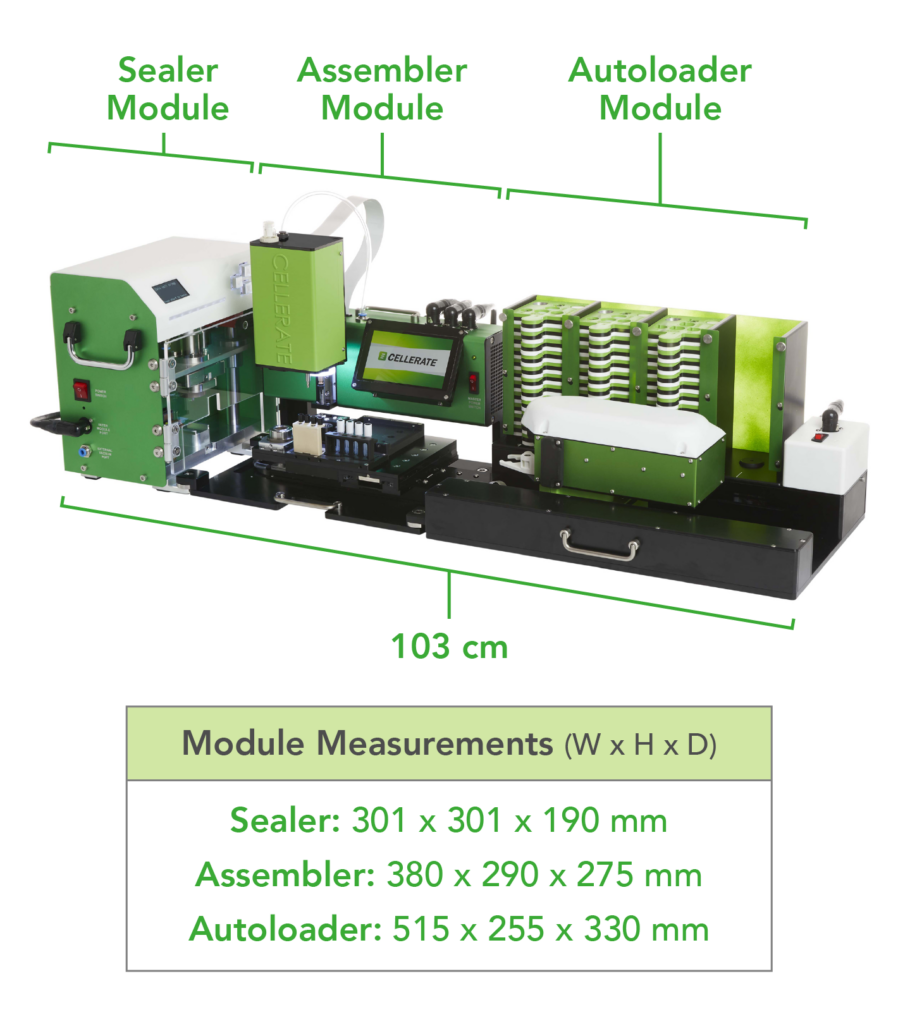

Sealer Module

Features & Specifications

General Features & Specifications

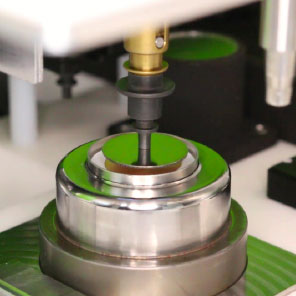

– High quality coin cell crimper

– Use as standalone unit or automated system module

– Compatible with all standard coin cell sizes

– Coin crimping force: 9.8-1.6 kilo-tons force

– Argon glovebox compatible; fits through antechamber

– Dimensions: 301 x 301 x 190 mm (W x H x D)

– Weight: 12 kg

Pouch Cell Features & Specifications

– Swap between coin and pouch cell sealing in 5 minutes

– Seal pouch cells with electrodes up to 40 x 60 mm

– Pinching force: 0.1 kilo-tons force

– Sealing Temperature: 120-160°C (top/bottom separately configurable)

– Internal vacuum pump: Up to 500 mbar

– External pump port for stronger vacuum

Assembler Module

Features & Specifications

– Assemble both coin cells and single-layer pouch cells

– Less than 0.2 mm electrode misalignment

– Create, save, and load cell build routines

– Approx. 12-24 cells per hour

– Cell build quality report automatically generated

– Argon glovebox compatible; fits through antechamber

– Automatic head exchange to avoid cross-contamination

– 5-200 µL liquid dispensing

– Compatible with Li foil electrodes

– Compatible with all common separator materials

– Compatible with all common electrolytes

– Compatible with curved electrodes

– USB, Wi-Fi, and Ethernet connectivity

– API for LIMS integration

– Dimensions: 380 x 290 x 275 mm (W x H x D)

– Weight: 10 kg

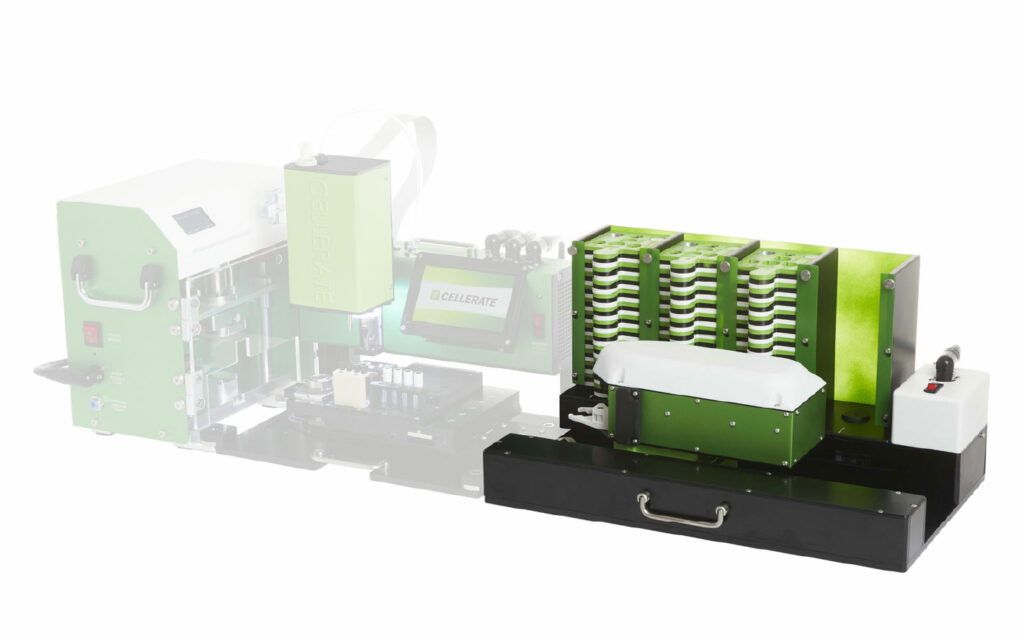

Autoloader Module

The Autoloader module enables 100 cells to be built unattended as standard, and can be expanded to build more

Features & Specifications

– Enables assembly of 100 cells unattended

– Create, save, and load routines for batch cell building

– Make every cell unique to explore parameter space

– Set-up time approx. 1 hour for 100 cells

– Unattended run time approx. 6-8 hours for 100 cells

– Compatible with both coin and pouch cells

– Tray tagging for easy cell identification

– Argon glovebox compatible; fits through antechamber

– Dimensions: 515 x 255 x 330 mm (WxHxD)

– Weight: 10 kg

System Specifications

Full System

Features

– Fully automated cell assembly

– Fits through glovebox antechamber

– Assembles up to 20 cells per hour

– Patented machine vision technology

– Mean electrode alignment within 100 μm

– User friendly interface

– 5-200 μL robotic micropipette

– Automated head exchange avoids cross contamination

Sealer Module

Features & Specifications

General Features & Specifications

– High quality coin cell crimper

– Use as standalone unit or automated system module

– Compatible with all standard coin cell sizes

– Coin crimping force: 9.8-1.6 kilo-tons force

– Argon glovebox compatible; fits through antechamber

– Dimensions: 301 x 301 x 190 mm (W x H x D)

– Weight: 12 kg

Pouch Cell Features & Specifications

– Swap between coin and pouch cell sealing in 5 minutes

– Seal pouch cells with electrodes up to 40 x 60 mm

– Pinching force: 0.1 kilo-tons force

– Sealing Temperature: 120-160°C (top/bottom separately configurable)

– Internal vacuum pump: Up to 500 mbar

– External pump port for stronger vacuum

Assembler Module

Features & Specifications

– Assemble both coin cells and single-layer pouch cells

– Less than 0.2 mm electrode misalignment

– Create, save, and load cell build routines

– Approx. 12-24 cells per hour

– Cell build quality report automatically generated

– Argon glovebox compatible; fits through antechamber

– Automatic head exchange to avoid cross-contamination

– 5-200 µL liquid dispensing

– Compatible with Li foil electrodes

– Compatible with all common separator materials

– Compatible with all common electrolytes

– Compatible with curved electrodes

– USB, Wi-Fi, and Ethernet connectivity

– API for LIMS integration

– Dimensions: 380 x 290 x 275 mm (W x H x D)

– Weight: 10 kg

Autoloader Module

The Autoloader module enables 100 cells to be built unattended as standard, and can be expanded to build more

Features & Specifications

– Enables assembly of 100 cells unattended

– Create, save, and load routines for batch cell building

– Make every cell unique to explore parameter space

– Set-up time approx. 1 hour for 100 cells

– Unattended run time approx. 6-8 hours for 100 cells

– Compatible with both coin and pouch cells

– Tray tagging for easy cell identification

– Argon glovebox compatible; fits through antechamber

– Dimensions: 515 x 255 x 330 mm (WxHxD)

– Weight: 10 kg

FAQs

The Cell Assembly and Sealing System (CASS) can make any size coin cell. It can also make single-layer pouch cells with up to 40 x 60 mm electrodes, including custom geometries. The CASS cannot produce multilayer cells as there are no in-built tab welding capabilities, so tabs must be welded onto electrodes before placing them in the system.

A proto-cell is essentially a coin cell in a pouch casing. This format enables users to control the pressure more precisely, and add a reference electrode (third electrode) to see how the voltage of each electrode changes individually while charging and discharging.

The throughput of the CAS System depends on the build configuration, but on average, it is 2.5 to 5.0 minutes per cell, so 12 to 24 cells can be built per hour.

Yes, there is an API for the Cellerate system, which uses Python. This makes integrating the system with LIMS (Laboratory Information Management System) easy.

Can’t find what you’re looking for? We provide customised systems to meet your needs.

Let’s talk

Want to make better batteries faster? Contact us!